Innovation

ELANTAS has been a market leader for more than six decades in the speciality business of liquid electrical insulating materials due to our prowess in new product development, technological upgrading, and close interactions with end users.

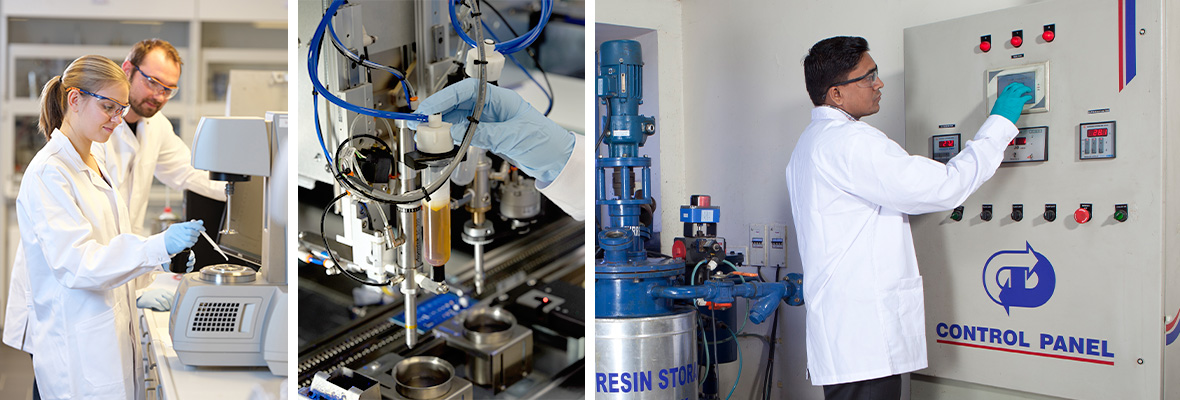

Research and Development

ELANTAS Beck India Ltd. has a strong team of chemists who explore various speciality chemicals to meet the ever-changing demands of the electrical and related industries. ELANTAS Beck India’s Research and Development (R&D) spending has always been top in the segment to ensure customer satisfaction.

Milestones in Research and Development

- Special polyesterimide wire enamels for the Russian market

- Environmentally friendly polyester wire enamels

- Class 180 high-speed polyesterimide wire enamels

- PEI enamel with hyper-branched polymer chemistry and less cresol

- PAI enamel with high molecular weight suitable for rectangular conductors with Class 220 applications

- Water-soluble core plate varnishes

- Pigmented unsaturated polyester resins for impregnation of electrical machines

- Class 180 water-soluble impregnating varnish

- Single-component epoxy resin for electronic applications

- Fire-retardant resins

Technical Service and Application Labs

Developing the latest technological products is not sufficient – they also need to be used properly. Various application techniques play vital roles in the performance of ELANTAS Beck India products. Our team of technical service experts always ensures easy acceptance of innovations in the market place. ELANTAS Beck India has introduced the following initiatives to meet the ever-changing market requirements:

- Technical symposia: ELANTAS Beck India has set up this platform to exchange information on innovations and technological developments and created an opportunity for customer-to-customer sharing of best practices. Over the years, it has been observed that our customers benefit from these workshops through increased productivity and process and cost optimisation. Click here for our training calendar.

- Process audits: Most of our customers have gained benefits from our process audits as they have helped them to increase their productivity through process optimisation, incorporating safety aspects, waste reduction, or improved product reliability. This helps the environment by reducing material and resource wastage.

- Collaborative initiatives: Our customers are working on Six Sigma projects for insulation systems. ELANTAS is actively participating in those initiatives to enhance standards.

- Pilot plants for trials: The benefits of new technologies need to be observed before customers make an investment in the technology. ELANTAS conducts application trials on customer components at a technical service laboratory. Once the tests show the benefit, customers can use the technology.