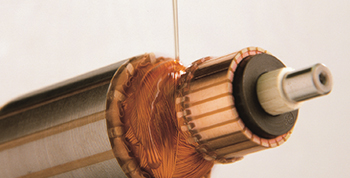

The clean and dry object is dipped into the varnish or resin - dipping time is dependant on the individual system and product design.

Air-drying finishing varnishes can be completely dried / cured at room temperature with the process being accelerated with the use of heat at temperatures up to 90°C. When using air-drying varnishes the user has to make sure that all coated surfaces have to be directly in contact with air.

Impregnating varnishes or resins are drained for a certain time at room temperature, after which the product is then cured in an oven at the temperatures and periods of time given on the product specification sheet. For large objects or those with complicated winding structures a two-stage curing process could be recommended. To better anticipate the time and energy consumption necessary for the objects to be impregnated, heating curves and curing temperatures should be available.

To start the Hot-dip UV process firstly the machines winding should be preheated by current. The correct pre-heat temperature is achieved by application of differing levels of current depending on the size and the dimension of the winding / machine. With winding at a temperature in the range of 130 – 150°C the parts are normally dipped into the resin for 1-2 minutes and then drained for 5-10 minutes.

For resins without potentially explosive monomers the current heating could be maintained during the dipping and drainage process. Curing is also achieved with the use of current heating. The additional exposure to UV rays for approx. 2-4 minutes provides for rapid curing of the exposed areas of the machine core, the tying tapes, as well as other insulating materials. With this process method short cycle times and a complete filling of the winding can be achieved. Additional cooling of the resin tank should be ensured to guarantee sufficient tank stability.

For the dip-roll process the parts have to be preheated to temperatures of 80-130°C in order to achieve quickly the gelling and curing temperatures. The resin is stored into in a small dipping tank and preferably stators are applied by rotating into the dipping tank. In order to avoid any dropping losses preheating temperatures, rotation speed and dipping depth have to be well adjusted. The resin immediately adopts the temperature of the winding, becomes considerably more thin fluid and is distributed uniformly through-out the winding as a result of rotation and capillary force. Curing occurs by circulating air. It recommended to keep the rotation running the first curing period.

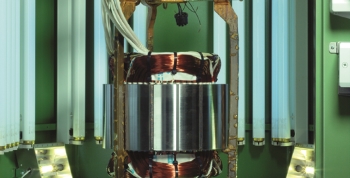

When using VPI equipment the clean and dry object could be dried with vacuum even before the impregnating process starts.

Impregnation takes place under a vacuum of 50 - 0,01 mbar at differing times and temperatures depending on the resin / varnish and object type. After the vacuum cycles the impregnation process is continued with an over pressure in the range of 1 - 6 bar. The total process cycle will be dependant upon the object type and resin system utilised.

Objects impregnated with varnishes or resins are drained for a specific time at room temperature prior to the product being cured in an oven. Times and temperatures will vary depending on the object type and size as well as the time given. Depending on the resin / varnish system a two-stage curing process could be recommended. To better anticipate the time and energy consumption necessary for the objects to be impregnated, heating curves and curing temperatures should be considered.

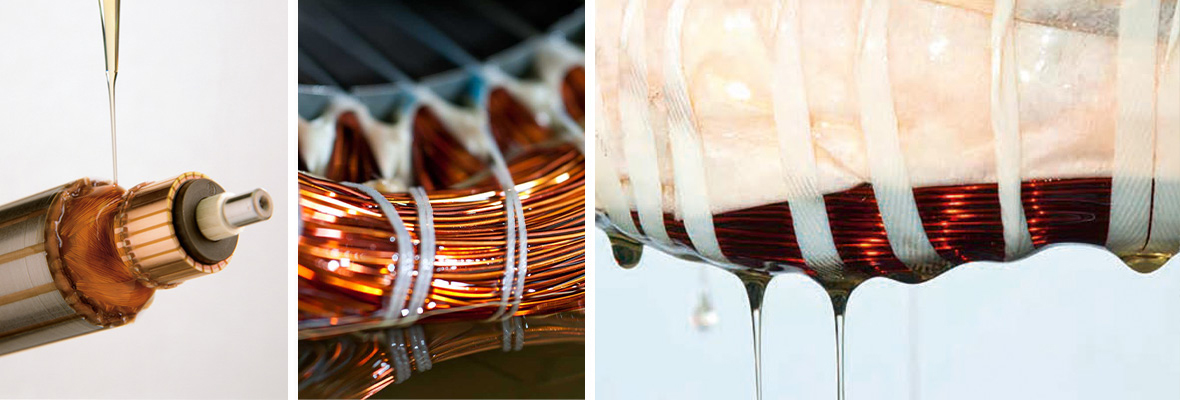

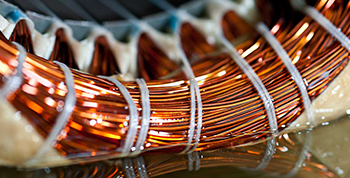

For the trickle process, parts typically have to be preheated to temperatures in the range of 80-130°C in order to achieve rapid gelling and short curing times. Due to the highly reactive nature of trickle resins they are commonly supplied as 2 component systems. The highly reactive nature of theses systems is better suited if the resin in the mixing and storage containers of the trickling plant does not exceed 25°C.

Resin is applied in a constant thin stream directly onto a rotating and preheated winding. Parts can be fixed inclined with trickling being done from only one side or fixed vertically with trickling done from both sides. In order to avoid or minimise any drainage losses preheating temperatures, rotation speed and flow rates have to be well adjusted. Once in contact with the winding, the resin immediately adopts the temperature of the winding, becomes considerably reduced in viscosity and is distributed uniformly through-out the winding as a result of rotation and capillary forces. Curing occurs by current heating and/or heated circulating air. It recommended that rotation is continued during the initial gel / cure phase.

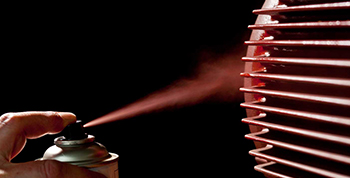

Application of coatings by spraying is used in order to protect surfaces against humidity and chemicals. All products should be thoroughly mixed by stirring before application. To facilitate spraying it may be necessary to add additional recommended thinners to the base product up to the level of approximately 20%.

Heating the objects to be sprayed to 50 - 60°C can be favourable when manufacturing techniques require a more rapid cure. If necessary, a second layer of varnish could then be applied after only 10 - 20 minutes. Products typically used for spraying are designed to be air-drying and as such product containers should remain closed and sealed before and after use to prevent evaporation of the solvents and undesired reactions owing to oxidative curing. Some finishing varnishes are delivered in spray cans ready to use.

Coatings can be applied by brushing in order to protect surfaces against humidity and chemicals. All products should be thoroughly mixed by stirring before application. Normally undiluted varnishes should be brush applied in a single coat and produce a homogeneous film build. Drying is done either by air at room temperature or up at temperatures up to 90°C.

Products typically used for brushing are designed to be air-drying and as such product containers should remain closed and sealed before and after use to prevent evaporation of the solvents and undesired reactions owing to oxidative curing.