For the trickle process, parts typically have to be preheated to temperatures in the range of 80-130°C in order to achieve rapid gelling and short curing times. Due to the highly reactive nature of trickle resins they are commonly supplied as 2 component systems. The highly reactive nature of theses systems is better suited if the resin in the mixing and storage containers of the trickling plant does not exceed 25°C.

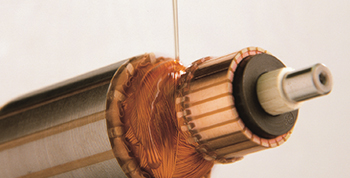

Resin is applied in a constant thin stream directly onto a rotating and preheated winding. Parts can be fixed inclined with trickling being done from only one side or fixed vertically with trickling done from both sides. In order to avoid or minimise any drainage losses preheating temperatures, rotation speed and flow rates have to be well adjusted. Once in contact with the winding, the resin immediately adopts the temperature of the winding, becomes considerably reduced in viscosity and is distributed uniformly through-out the winding as a result of rotation and capillary forces. Curing occurs by current heating and/or heated circulating air. It recommended that rotation is continued during the initial gel / cure phase.