Email us on advancedPrinting@altana.com

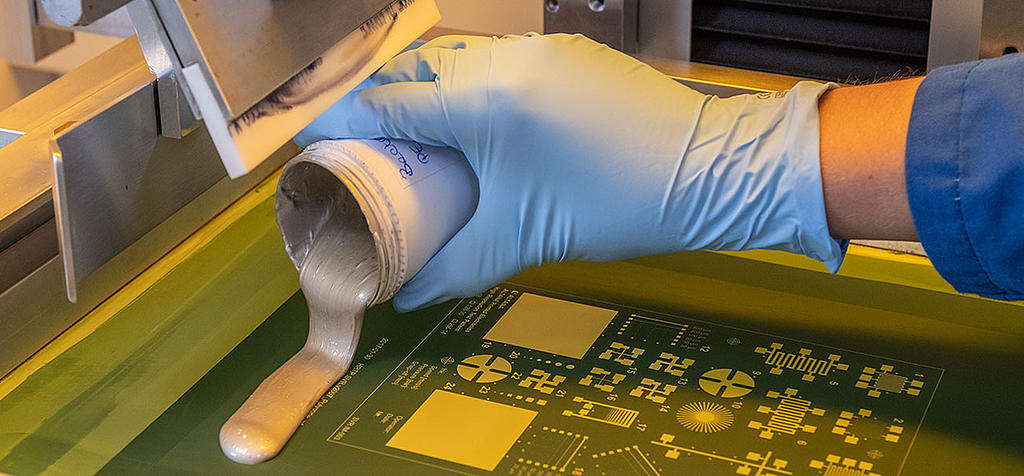

The Printed Electronics Department of ELANTAS Europe develops and produces functional screen-printing pastes. These differ in their electrical properties and also in their compatibility with other pastes and substrates. Indeed, in respect of their workability and printability it is necessary to take their specific characteristics into account. For example, the solvent employed influences the screen open time, i.e. the longer a paste dries, the longer the screen meshes remains open and can be continually filled with ink.

Particularly in a production environment with longer interruptions or higher room temperatures, slowly evaporating solvents can be advantageous in order to guarantee reproducible quality.

If the performance of the existing drying plants is limited or temperature-sensitive substrates are used, fast-drying pastes are recommended. However, if the interruption of the printing process is excessively long, screen meshes can become clogged. In order to minimise the cleaning effort, the duration of a maximum production interruption should be specified in accordance with the material used.

For these reasons, in the interest of efficient production it is essential to have a knowledge of one’s own processes in order to define the required materials and material properties.

As a rule, for UV-hardening pastes the screen open time is not problematic, provided that no UV light reaches the corresponding material, for example by scattering from machine parts. However, high temperatures, impurities or superimposed pastes can influence the printed result sub-optimally.

In general, adherence to the recommended storage conditions, for both the solvent and the UV-hardening pastes, improves the product reliability.

The Printed Electronics Bectron? products are distinguished by a variety of material properties. Functional screen-printing pastes are developed continually, according to the requirements of our customers. If you’re looking for an optimally matched material system for your existing machine park, we would be pleased to advise you with the choice of materials and the optimization of your processes. Together with you, we can also investigate the feasibility and implementation of your ideas and projects for the development of a new material.

For questions about the choice of appropriate materials or application-specific topics, please feel free to contact us directly under advancedPrinting@altana.com

Learn more about our portfolio for printed electronics.